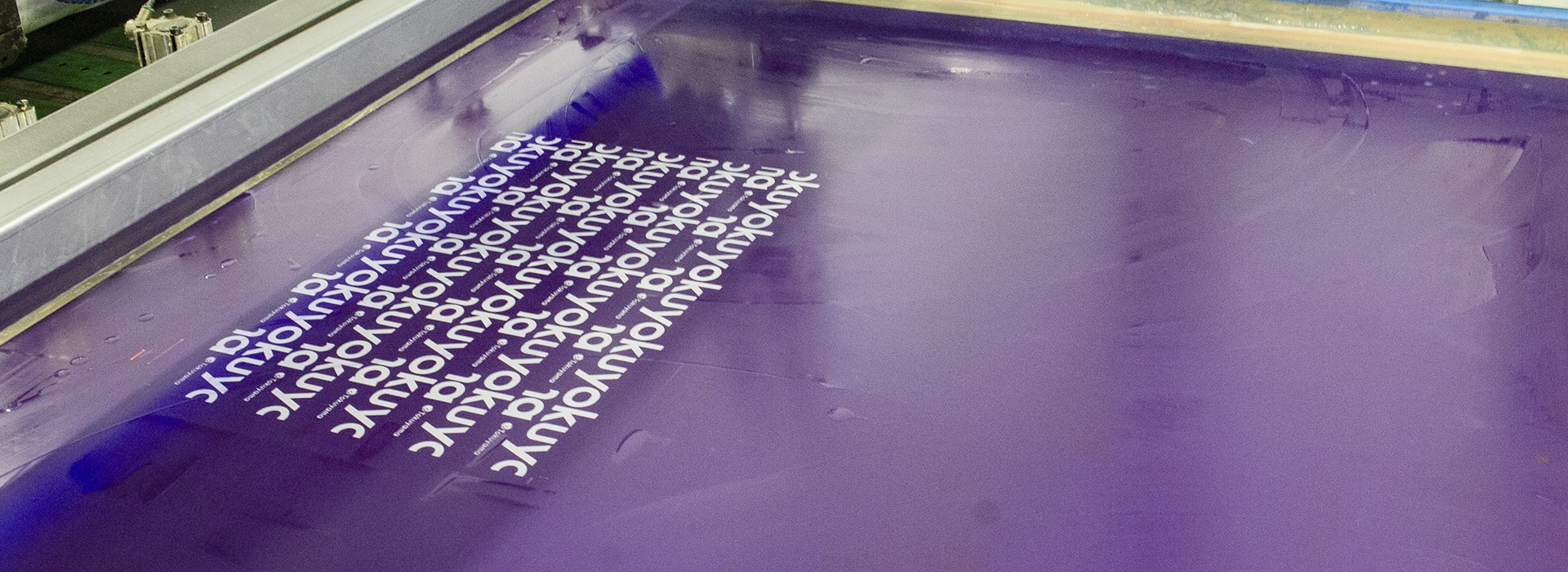

UV VARNISH SCREEN PRINTING

OF PAPER AND CARDBOARD

UV screen printing varnishing is a technique for transferring inks onto various types of substrates using a finely woven mesh stretched over a frame.

The image to be varnished is transferred to a transparent film and placed on the frame. The areas of the mesh that are not to be painted are blocked, while the areas that correspond to the image remain permeable to the paint.

Because of its ability to apply relatively thick layers of varnish, UV varnish screen printing enhances images, texts and corporate brands.

The continuous evolution of screen printing has helped to make it one of the most widely used and valued printing techniques in a wide variety of industries and creative fields.

Over the years, screen printing has evolved to improve its accuracy and efficiency. For example, the use of automated machinery has allowed for faster and more accurate output while reducing the need for manual labor. In addition, advances in mesh materials, inks, and varnishes have expanded the creative and technical possibilities of screen printing.

Types of UV varnish screen printing

Screen printing with glossy and matte UV varnish:

- Materials: Paper and cardboard, also laminated.

- Printing Process: Varnish applications to emphasize the gloss-matte contrast.

Screen printing with glitter:

- Materials: Paper and cardboard, also laminated.

- Printing process: Application of tiny polyester flakes in the varnish to create a shiny effect.

Thick screen prints:

- Materials: Paper and cardboard, also laminated.

- Printing Process: Application of varnish to create a thicker visual and tactile effect.

Applications

Due to its versatility, screen printing is used in a wide range of fields. Here are some of its main areas of applications:

- Publishing: Printing book covers, magazines and catalogs.

- Packaging: finishing of packages, boxes and cases.

Characteristics

- Materials: Paper and cardboard, also laminated.

- Maximum format: 1000 x 1400 mm.

- Maximum thickness: 700 grams per square meter.

Choose A. Zaccaria, where artistry in screen printing meets innovation.

Contact us today to find out how we can add value to your project with our years of experience!