PAPER AND CARDBOARD LAMINATION

The Zaccaria family has been a symbol of excellence in the graphic processing and lamination of paper, cardboard and packaging for more than 60 years.

The high quality of its services has always ensured the full satisfaction of its customers, who, thanks to the trust they have built up, have continued to choose A. Zaccaria decade after decade.

This commitment is combined with an unwavering focus on efficiency, innovation and environmental sustainability, making A. Zaccaria a benchmark in the industry.

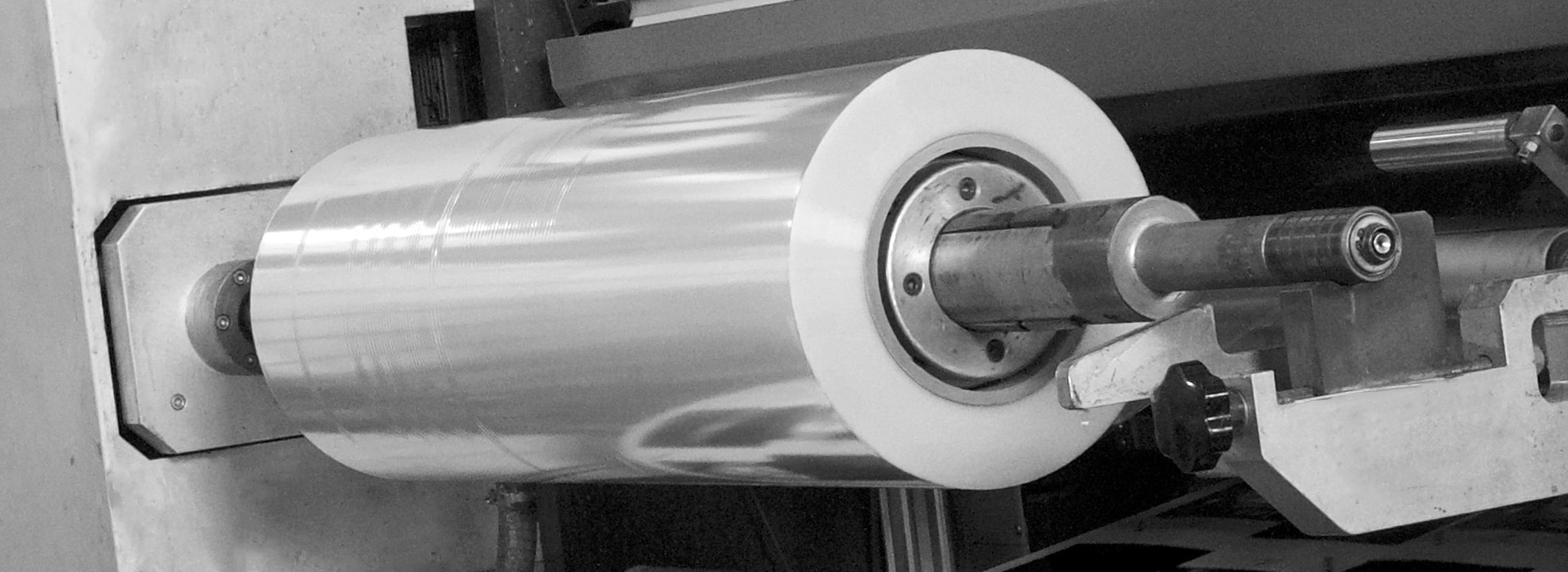

Lamination occupies a prominent place among the services offered.

This is a process in which a plastic film is applied to printed material, representing an ideal solution for aesthetically enhancing the aesthetics of the finished product and ensuring greater durability by protecting it from abrasion, scratches, humidity and other external factors.

In other words, printed products that are not laminated are more susceptible to wear, fading, and damage caused by adverse environmental conditions.

Types of lamination offered by A.Zaccaria

A. Zaccaria offers a wide range of laminations in polypropylene or polyester, suitable for food contact. These laminations offer greater strength and durability, while providing a high quality finish.

Lamination types:

- Solventless lamination: solventless lamination is an environmentally friendly process that eliminates the use of solvents, reducing emissions of volatile organic compounds (VOCs). It is ideal for projects related to the food industry and children’s products, and ensures an excellent finish.

- Dry lamination: This type of lamination uses pre-glued films without the use of solvents that are activated by heat, allowing for fast processing and good gloss.

- Water-based lamination: Water-based lamination is environmentally friendly and provides excellent adhesion to difficult substrates. Ideal for metallized substrates and other special applications.

Types of finishes

- Glossy and matte finishes: Glossy finishes provide an extra shine that enhances the colors and aesthetics of the product. Matte finishes provide an elegant and sophisticated look.

- Soft touch: soft touch lamination provides a soft, velvety surface that enhances the tactile experience and adds a touch of luxury to the finished product.

- Heat seal: ideal for creating strong seals.

- Double coat: double coat lamination is ideal for adding an extra layer of protection and a high quality finish that is perfect for gluing.

- Holographic: a three-dimensional finish, ideal for eye-catching and distinctive visual effects.

- Cloth-like: fabric-like lamination offers a unique texture that simulates the look of fabric, ideal for art or design projects.

- Glossy silver and gold: These metallic finishes add a touch of elegance and a premium look to products, perfect for luxury packaging or promotional materials.

- Scratch-resistant: Scratch-resistant lamination provides extra protection against scrapes and scratches, keeping products in optimal condition for longer.

All types of lamination offered by A. Zaccaria are produced with the latest technology and high quality materials, ensuring optimal results and environmental friendliness.

Application for lamination

Lamination is widely used in various industries because of its ability to enhance the appearance of materials and protect them:

- In all industries (e.g., cosmetics, pharmaceuticals, clothing) and especially in the food sector, packaging lamination is crucial to ensure the strength and protection of packaging, where the use of plastic films suitable for food contact is a standard;

- in the publishing industry, it is essential for magazines, books and brochures, giving them a glossy or matte finish that enhances their appearance;

- in the graphics and advertising industry, lamination helps create durable and attractive promotional materials;

- It is also used in the industrial sector to protect labels and components;

- Finally, in the education sector, laminating educational materials and posters ensures their longevity

Characteristics

- Materials: Paper and cardboard.

- Maximum format: 1400 x 1600 mm.

- Maximum thickness: 700 grams per square meter.

Choose A. Zaccaria, where quality meets innovation.

Contact us today to find out how our years of experience can enhance any of your products!